| Boilers Locomotive design Home page |

|

| Boilers Locomotive design Home page |

|

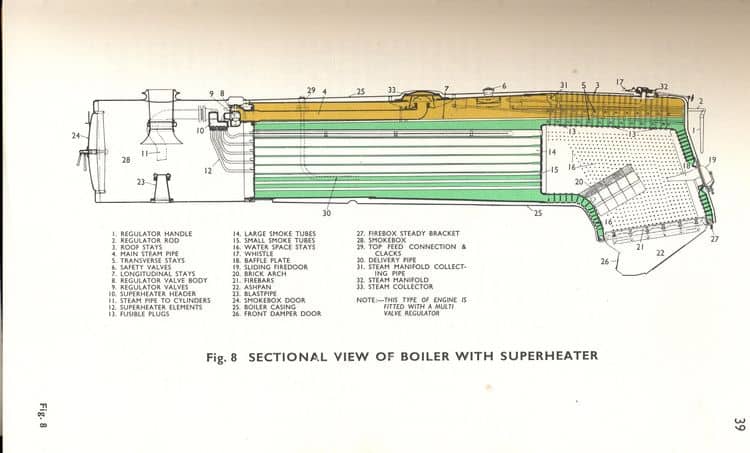

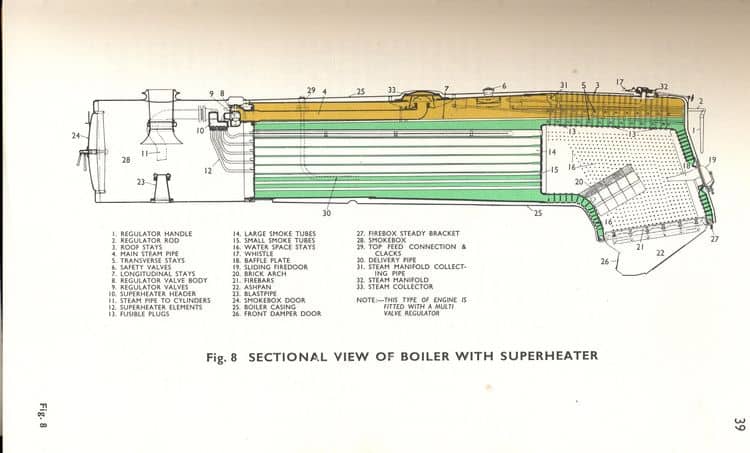

Above from British Transport Commission. Handbook for railway steam locomotive enginemen

Cook,

A.F.

Raising steam on the LMS: the evolution of LMS locomotive boilers.

Huntingdon: RCTS, 1999. 233pp.

Part of the complex RCTS History of LMS locomotives. Includes much

information relevant to boiler design on other railways..

Hills, Richard L.

Power from steam. 1989.

Here it is interesting to note that the Great Western Railway, which

used Welsh coal in its locomotives, retained a narrow firebox for its most

powerful 4-6-0 King class engines in 1927 whereas the London & North

Eastern Railway employed a wide firebox for the 4-6-2 Flying Scotsman in

1923 because the calorific value of its coal was not so high.

Combustion chambers

Some boiler developments slipped through without making a "big splash"

at the time. Thus the application of the combustion chamber principle to

narrow fireboxes of the Belpaire type, as on the Patriot and Royal Scot classes

noted by Cook above around page 78 emerged during the discussion of

Wagner's influential paper (No. 253)

and in the discussion contribution

made by Herbert Chambers and a response to it by

James Clayton. It is here that

the "sloping tube plate" terminology adopted mainly retrospectively

emerged

Sloping throat plate designs

Cook (above): The increase

in firebox volume produced by a sloping throatplate, and, even more so, by

a full combustion chamber, was of more importance in fireboxes burning "long

flame" Northern coals than with South Welsh coals.

It is likely that, in most British locomotives, the increase in volume due

to the sloping throatplate was of more importance in lengthening the path

of the flames before they entered the tubes (and thus allowing more time

for complete combustion) than for the increase in radiant heating surface

which it provided. Certainly this was the view of Herbert Chambers, who was

Chief Locomotive Draughtsman at Derby from 1923 to 1934.

A quite different effect of the sloping throatplate was that it reduced the

weight of the boiler (by replacing the rear section of the tubes by empty

space). This had the effect of moving the centre of gravity of the boiler

forwards, and it could, in some designs of locomotive, assist in getting

the weight distribution right. An example of this was the GWR Manor Class

4-6-0, for which the new No 14 boiler was designed, this being the first

Swindon narrow-firebox boiler to have a sloping throatplate, and which steamed

badly until its draughting was sorted out by S.O. Ell's team.

The sloping throatplate first appeared in Britain in December 1902 in the

Ivatt Large Atlantics of the GNR, whose firebox was, by British standards,

short for its size. The sloping throatplate added about 6in to the length

of the firebox. The LBSCR Atlantics, being based on the Ivatt design, followed

suit. The next British locomotive with a wide firebox was The Great Bear

of the GWR in February 1908. This had a sloping throatplate, but, unlike

all subsequent British Pacifics, it had no extension of the firebox beyond

the throatplate. It was the only GWR locomotive to have a sloping throatplate

until the Manor 4-6-0 of 1937.

The first British sloping throatplate in a narrow-firebox boiler appeared

in December 1913 on the GNR in the first of Gresley's 2-8-0s (later LNER

Class O1, later changed to O3) Thereafter all Gresley's larger engines had

sloping throatplates, which lengthened the firebox by between 6in and

15½in.

A sloping throatplate produced a corresponding reduction in the length of

the tubes as compared with similar boiler with straight throatplate In engines

with narrow fireboxes set partly between the rear coupled axles, such as

2-6-0s and 4-6-0s, this reduction was no advantage, as the greater tube length

could be used effectively. On the other hand, in engines with wide fireboxes

behind the coupled wheels, particularly six-coupled engines, the length of

the barrel had necessarily to be 20 to 26 feet to span the coupled wheels,

and it was difficult to fit correctly-proportioned tubes of this length.

In these engines, a forward extension of the firebox into the barrel could

be used to reduce the length of the tubes.

The first British Pacifics illustrate this point In The Great Bear

the barrel and the tubes were both 23ft long, but the next types, Gresley's

on the GNR and Raven's on the NER, had combustion chambers. In Raven's design,

with no taper on the barrel or firebox, the barrel itself was 26ft long,

but a combustion chamber of length 3ft 6in, and a front tubeplate recessed

1ft 6in into the barrel, together reduced the tube length to 21ft. In Gresley's

boiler the sloping throatplate and combustion chamber added 3ft to the length

of the firebox, and the tubes and barrel were 19ft in length, but in the

later boilers ot the A4 Pacific and the V2 2-6-2 the combustion chamber was

increased to 4ft.

Up to the Grouping the only other British types with sloping throatplates

were the 4-6-4Ts of the GSWR and LBSCR, in which the slope added 6in to the

length of the firebox. The only British boiler with a narrow firebox and

a true combustion chamber was the experimental boiler fitted to SR Lord Nelson

857 between 1937 and 1945. As the steaming of this engine was inferior to

that of the standard engines of the class, there was no incentive for the

SR to continue this experiment, although subsequently all the Bulleid Pacifics

had combustion chambers.

Developed by Brown Boveri in Switzerland. High velocity combustion, high velocity water and high velocity steam. Experimental application to old PLM four-cylinder compound 4-6-0 in 1938.

Duffy, M.C. The Velox boiler

and its application to railway traction. Trans Newcomen Soc.,

1999/2000, 71, 229-56.

Meyer, Adolph. The Velox steam generator: a super-charged boiler. J. Inst.

Fuel, 1934 (August) 316-35.

Rutherford, M. Bogie steam locomotives. Part 2. Backtrack, 1998,

12, 387-93 (p. 388)

Feed water heaters

Sauvage, Edouard. Feed-water heaters for

locomotives. Proc. Instn Mech.

Engrs., 1922, 103, 715-34.

Principal appliances in actual use were the Davies and Metcalfe injector,

Weir heater, Caille-Potonie Heater, Worthington heater and Knorr heater.

Metcalfe, Richard. Davies &

Metcalfe Ltd: railway engineers to the world. 1999. 208 pp. 142

illus.

See also Metcalfe page Very

detailed account of every type the firm produced from the very first invented

by James Metcalfe with the financial assistancve of Davies, a railway and

colliery magnate., many of which are identified by letters, also the Monitor

type.

Safety valves

Skeat, W.O. Discussion on Tuplin, W.A. Some questions about the steam

locomotive. J. Instn Loco. Engrs,

1953, 43, 679-81. (Paper No. 528).

The craze for Pop safety valves was unjustified, and many thousands

of pounds worth of perfectly good Ramsbottom valves had been foolishly thrown

away, in the past, in the hope that the virtues of " Pop" valves would justify

the change.It was much easier to make a valve pop off its seat as the pressure

rose than to make it pop on to its. seat as the pressure fell. If the range

through which the valve operated were small, there was the risk of the valve

failing to reseat properly, with consequent loss as steam continued to dribble

to atmosphere. If the range were wide enough to ensure perfect reseating

of the valve, then much steam, coal, and water were wasted. A great volume

of water was frequently blown off with the steam when Pop safety valves were

in action on (say) the Standard Class 7 Pacifics; the valves usually lifted

at 250 lb. per sq. in. and reseated at 240 lb. per sq. in. Here, surely,

the actual waste of heat was not merely that contained in the escaping steam,

but the difference between the total heat stored in the boiler at the higher

pressure and that stored in the boiler at the lower pressure.

The total coal theoretically burnt to waste each time a valve lifted (assuming a calorific value of 12,000 BTU/lb) would seem to be rather over 16 lb. Since the boiler efficiency probably would not exceed 90%, the actual amount of coal might be 18-20 lb.enough for a few lifts of the valves to have a serious effect on coal consumption. Moreover, the working pressure in practice was the pressure at which the safety valve re-seated, not that at which it lifted; and the difference in these to pressures might be as much as 4%. The use of direct-loaded valves, such as those developed at Swindon, or of Ramsbottom valves, would confine the operating range to 2-3 lb. per sq. in., with a very considerable saving in coal, water, and steam.